Well hello there! I’m Julia Walther and I make pottery in Washington, DC.

My journey with pottery began nearly six years ago during my senior year of college when my ceramics professor told us that clay can do anything, you just have to ask it at the right time. That mix of constraints and possibilities is a large part of why I’m so in love with ceramics.

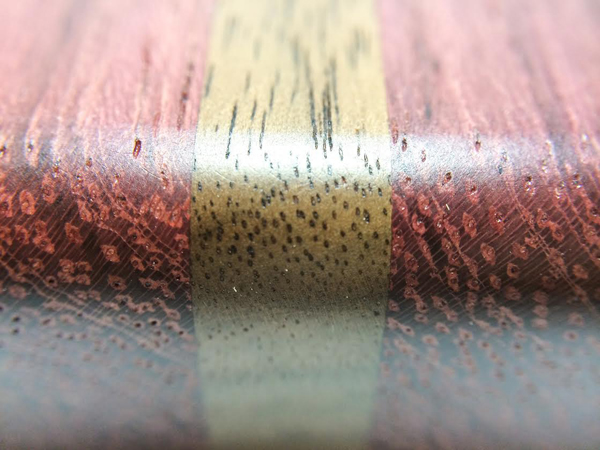

I throw almost all of my work on the wheel using a porcelaneous stoneware that’s a beautiful creamy color when fired. I then spend most of my time decorating those pieces with slips and colored underglazes and carving back through the layers to reveal the bare clay underneath. In the midst of those decorative choices, I’m constantly surprised by threads of ideas that can lead my work down completely new paths.

The cacti decorations have come out of my appreciation of papercutting, and other folk crafts that use abstracted shapes to convey stories and show evidence of the human hand. I also really enjoy carving out the spikes!

After the glaze firing, I’ll choose a few pieces to which I’ll apply metallic luster accents and do another firing specifically for that. So your pot may have had a trial by fire three times before it ends up in your hands.

I work alongside about twenty artists working at Red Dirt Studio, a repurposed firehouse just outside Washington, DC. I love the community we’ve established through weekly seminar meetings and by sharing the building. It’s easy to accidentally isolate yourself as an artist, so I’m glad to have this flow of interesting people around my studio space.

At the same time, this is also the first instance in my career where I’ve had freedom to call nearly all the shots. I want to spend the precious time I have in the studio actually making work and taking care of my body to prevent injuries from overwork. In the last year, that has meant switching to a commercially produced pre-mixed clay, and changing the firing temperature of my work so I can use electric kilns, which tend to be more compatible with an urban environment. Additionally, for the past three years I’ve been throwing standing up, which will hopefully prevent future back issues related to sitting and leaning forward (the worst possible position for your back!).

Pots are special because they can be both a sculpture and a canvas. I’ve found a lot of joy in scribbling on the surfaces of my pots, freezing the movement of a hand in time. I’m excited about creating those juicy points of interest that ask you to turn the pot in your hands to soak up the details while you eat your meal or admire your flowers or engage with the piece in any other way. The last step of making pottery is getting it into the hands of the user, and that’s where a new adventure begins.

This will be my first year at the Art Star Craft Bazaar, and I’m so looking forward to the show! I’d love it if you stopped on by Booth #59 and said hello.

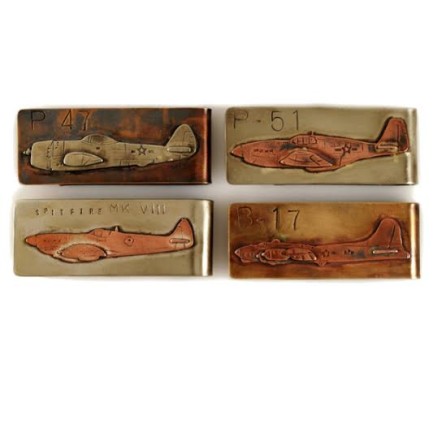

About Dreadnought Workshop: Brett is inspired by the city, American history, and the things he experiences living in an urban setting. Brett’s new line of belt buckles, tie clips, and cufflinks are made using various metal fabricating and casting techniques which he has learned through studio exploration.

About Dreadnought Workshop: Brett is inspired by the city, American history, and the things he experiences living in an urban setting. Brett’s new line of belt buckles, tie clips, and cufflinks are made using various metal fabricating and casting techniques which he has learned through studio exploration.

Audio Tree founder Daniel Knoll creates handmade wood products for smartphones and tablets, most notably the signature Iphone acoustic amplifier/docking station. He has over 15 years of woodworking and sound engineering experience which led to the development of Audio Tree LLC.

Audio Tree founder Daniel Knoll creates handmade wood products for smartphones and tablets, most notably the signature Iphone acoustic amplifier/docking station. He has over 15 years of woodworking and sound engineering experience which led to the development of Audio Tree LLC. These speakers have been tested in a professional recording studio and proven to double the sound of your phone’s speaker using “passive amplification” meaning there are no electronics involved. Some have been designed to allow you to charge your phone by running your own charger through the speaker.

These speakers have been tested in a professional recording studio and proven to double the sound of your phone’s speaker using “passive amplification” meaning there are no electronics involved. Some have been designed to allow you to charge your phone by running your own charger through the speaker.

For the first time Audio Tree will be at the

For the first time Audio Tree will be at the

Jeff inspecting the belts after our specially formulated spray coating is added to protect the images in the leather.

Jeff inspecting the belts after our specially formulated spray coating is added to protect the images in the leather.

Left: A Juki automatic sewing machine, which helps us put on the tags on all our tees.

Left: A Juki automatic sewing machine, which helps us put on the tags on all our tees.

Jamie will be be traveling from Washington, DC to join us at our

Jamie will be be traveling from Washington, DC to join us at our

We are excited to announce that our Art Star Pop Up Market will be back at

We are excited to announce that our Art Star Pop Up Market will be back at